Faced such a huge problem in terms of casting the plaster directly on the wooden base. Because pine is so soft and the surface I am casting on is relatively thin, the casting process caused the wood to bow terribly. I did some research and asked some people and found out that it is because a lot of water (the plaster top is pretty large) is entering one side of the wood, causing that side to expand and thus the piece to bow. I toyed with the idea of casting the plaster separately, but because of the nature of plaster, it is impossible to glue it onto anything. This problem almost forced me to abandon the entire idea and start from scratch.

Solved it by spraying the side that comes into contact with the plaster with enamel paint. The paint dries to a hard glossy finish, effectively waterproofing the surface of the wood. With no water entering the wood, it remains flat as it should be.

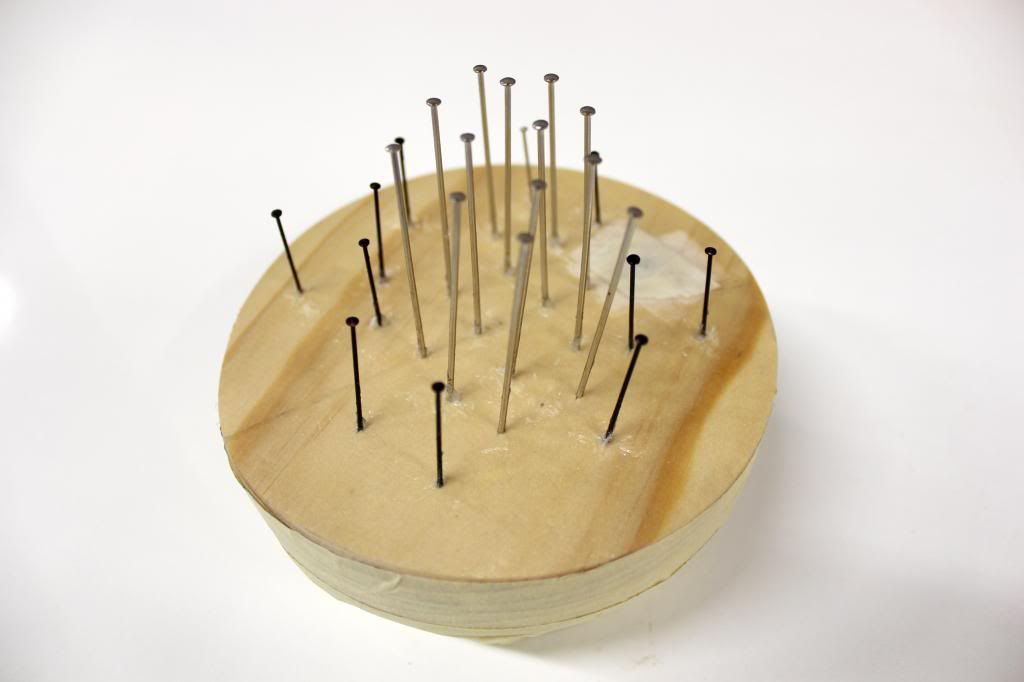

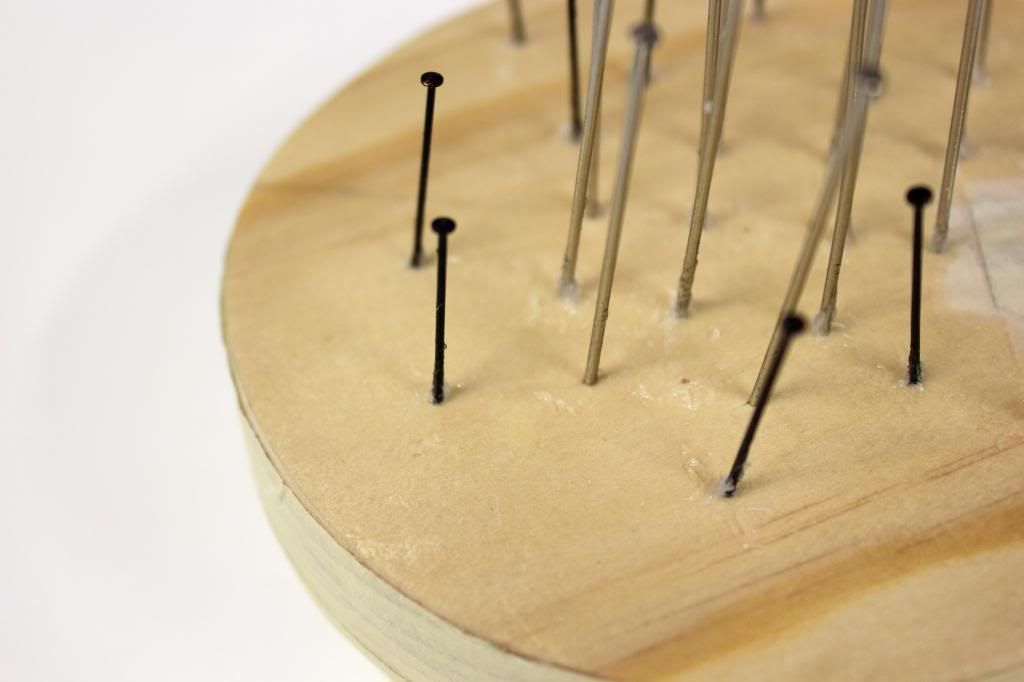

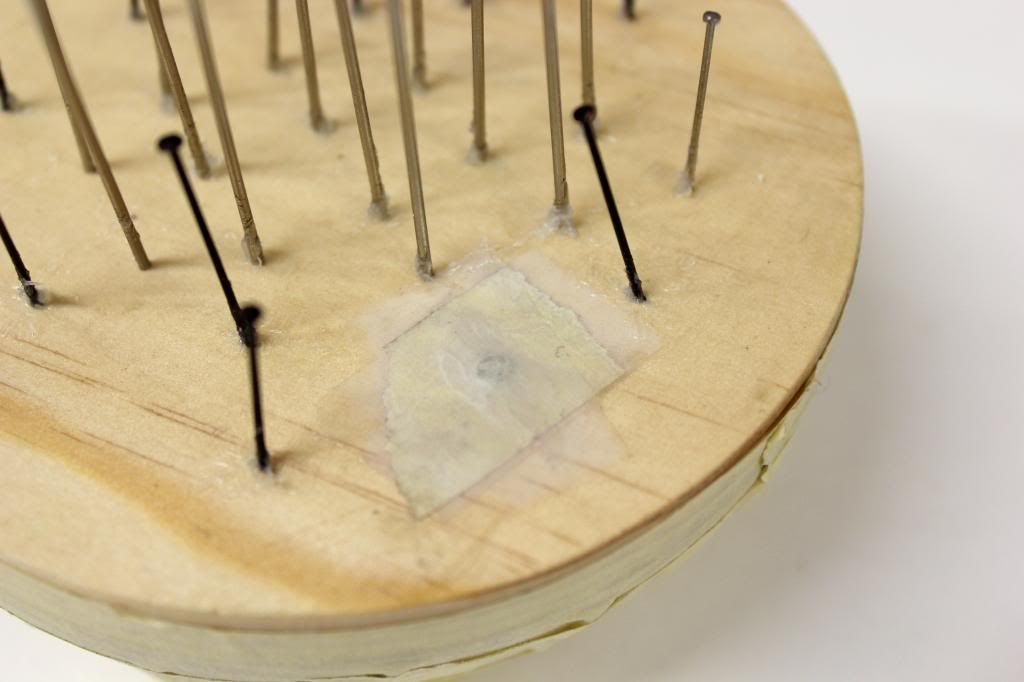

Quite a few nails were also put in, in varying heights and distances, so that when the plaster sets and cools down, it does not separate from the wood (happened with one of my failed models). However, the nails introduced pretty large holes on the surface which water can enter from, and the enamel paint was not able to seal the holes. I further coated them with generous amount of Vaseline, to seal the holes shut.

Also taped the top of the screw, if not, the plaster will set around the screw and the lid will not be able to pivot.

Labels: dsdn141

Post a Comment